Safety helmets are those which are used to wear by any person for protecting their head from any kind of injury during any work or activity. It is also called hard hat.

According to the Health and Safety Executive (HSE), 47% of estimated annual average injuries in the construction industry for the years 2017/18–2019/20, were from falls from a height and a further 12% of injuries were caused by being struck by moving, flying or falling objects.

It is very important to wear safety helmets as a Personal Protective Equipment (PPE) in workplace especially in construction site or workplace where there is risk of falling object or fall from height.

Helmets were invented around 2500 BC to protect soldiers’ heads during battles. The first mass-produced versions were worn by Assyrian soldiers around 900 BC and were mainly made from bronze, protecting the wearer from sword blows and arrow strikes.

In the Victorian era, workers such as miners would wear only a canvas cap in the mines, giving them no protection from falling objects. Similarly, a boom period for construction, shipping and engineering at that time, shipbuilders, dock and construction workers had no protective headwear to protect them when working, despite the dangerous work they were doing, although many employers were beginning to consider the wellbeing of their workforces.

For example, contractors William Arrol were noted at the time, as making every effort to look after the welfare of the “Briggers” (construction workers) working on the construction of the Forth Rail Bridge in the 1880s.

However, a description of the clothing worn by the men included “old tweed jackets, mufflers and caps” which although helping to keep out the worst of the Scottish weather, offered little or no protection against falling tools or red-hot metal. Seventy-three fatalities were recorded on that project, many from head injuries.

It was not until the late 1800s, that the Patent Pulp Manufacturing Co Ltd of Thetford in Norfolk, produced the first ever mass-produced hard hat to protect workers. The Patent Pulp Manufacturing Co Ltd manufactured a helmet from pulp which was mixed with lime and fed into formers. The formed hat was left to dry and then lacquered giving a smooth, if slightly textured, finish and then a steel plate was riveted to the inside of the helmet to give further protection. Although these helmets were groundbreaking, they were somewhat uncomfortable to wear due to the lack of a cradle inside the helmet. The cradle was not invented until about 30 years later in 1919, by an American.

The safety helmet workers wear today was actually came from the invention of the hard hat for the soldiers during war. The concept of wearing hard hat for a person’s own safety was first seen in wars.

Edward W. Bullard, (1893-1963) a veteran of World War I, invented the hard hat in 1919. It was inspired by the helmets worn by American doughboys. In the 1920’s, the first industrial hard hats went into mass production, made from steamed canvas, black paint and glue. These were the first protective caps developed specifically for industrial purposes, and were widely used on shipyards across the United States.

To know more details about the history of safety helmet please read this article “The History of the Hard Hat”

In OSHA 1926.100(a) states that “Employees working in areas where there is a possible danger of head injury from impact, or from falling or flying objects, or from electrical shock and burns, shall be protected by protective helmets.”

Safety helmet is mostly used in construction site where there is a high potential of falling objects on head. The heavy industries also use hard hat for their worker head protection. The power plants employee also uses hard hat for protecting their heads from getting contact with conductive wires or any electrocuted objects.

Hard hat has specific designs for specific types of works. So, when you need to buy a safety helmet, know which one is suitable for you.

There are many kinds of safety helmets. The primary classification is done into 2 types:

Type 1: Type 1 hard hats are designed to minimize the impact of forces from objects striking the top of the head. They are the most widely used helmets on worksites. These helmets offer protection against items like a falling hammer or tape measure.

Type 2: Type 2 hard hats are designed to absorb forces from lateral impacts, including strikes to the side, off-center areas, or the top of the head. Such impacts could result from the sharp edge of an I-beam or a swinging structural component of a tower. These helmets often feature high-density foam or suspension systems along the sides for added protection. This is most commonly used in construction and oil and gas industry.

In terms of electrical classes, the hard hats are classified into class G, E and C.

Class G (General):

Class G hard hats are intended to provide protection against low-voltage conductors, with a capacity to withstand up to 2,200 volts. Similar to Class E helmets, this protection is limited to the head. Previously, Class G hard hats were classified as “Class A.”

Class E (Electrical):

Class E hard hats are specifically designed to provide protection against high-voltage conductors, with a capacity to withstand up to 20,000 volts. These helmets are not permitted to have ventilation. Previously categorized under the “Class B” rating, Class E hard hats can also serve as General, or “Class G,” helmets.

Class C (Conductive):

Class C hard hats are classified as conductive and do not offer any electrical protection. These helmets are usually vented, providing impact protection while enhancing breathability for workers.

To know more about different types of safety helmet, please read this document.

There are some standards for safety helmet or hard hat:

ANSI/ISEA Z89.1-2014:

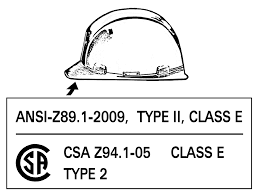

This standard defines performance and testing criteria for industrial helmets, commonly referred to as hard hats. It specifies types and classes of helmets based on the hazards they address.

OSHA 29 CFR 1910.135:

Establishes head protection requirements and classifications for hard hats and safety helmets used by general industry workers.

OSHA 29 CFR 1926.100:

Specifies head protection requirements and classifications for workers’ head safety.

It is suggested to wear an ANSI/ISEA Z89.1 certified hard hat in job sites. This option falls into the Type 1, Class E category.

How will you know if you are using a good quality safety helmet which ensures necessary protection from particular level of impact? There are different testing certificates of safety helmet where the manufacturer tests their products and release them in the market. These are labeled in the helmet. Turn the helmet upside down and try to find out this tag.

Here are the components or parts of a safety helmet.

When you conduct an inspection of a helmet, make sure these parts are properly working and in good condition.

If you want to buy Safety helmets shown in the picture please go here “SafeBuilder”. SafeBuilder provides best quality safety helmets which are industry friendly.

The service life of a hard hat begins when it is put into use, not on the manufacturing date stamped on it. The manufacturing date only indicates when it was made. Once the hard hat is put into service, the start date should be recorded on the label inside the shell.

The suspension system should be replaced within 12 months, and the hard hat itself should be replaced within 5 years at most. However, these are maximum timeframes, and regular inspections are essential to ensure the hard hat remains safe to use.

If the hard hat experiences an impact, it must be removed from service immediately. Even if there are no visible signs of damage, the materials may have weakened and may no longer provide adequate protection.

The following maintenance should be done for each safety helmet:

6. Never use a suspension that is not intended to be worn with a particular shell.

7. Never use a shell made by one manufacturer with a suspension made by another.

8. Painting hard hats are prohibited. ANSI Z89.1-2003 Appendix A4 states that caution should be exercised when painting hard hat shells since some paints and thinners may attack and damage the shell and reduce protection levels. The hard hat manufacturer should be consulted before painting.

4. After using the helmet store it in a clean, dry area that does not exceed 50 degrees Celsius. The manufacturers suggest to keep it within 20±15° in a suitable container. Do not store it in direct sunlight because UV rays can do significant damage over time to your hard hats.

5. Components of a hard hat can be replaced if it is damaged or when required. However, if the damage is due to an impact or incident, it is suggested to be replaced completely.

6. Helmets marked with a “reverse donning arrow” can be worn frontward or backward in accordance with the manufacturer’s wearing instructions. They pass all testing requirements, whether worn frontward or backward.

There are few ways to dispose a hard hat, including recycling, donating, or repurposing:

Recycling:

Many hard hats are made from high-density polyethylene (HDPE) or similar recyclable plastics. Before recycling, check if your local recycling facility accepts such materials. Remove non-recyclable components like straps, foam liners, or metal fittings. Clean the hard hat thoroughly to ensure it meets recycling standards. Once prepared, deposit it at a designated recycling center for proper processing.

Donating:

Hard hats that are no longer suitable for industrial use but remain in good condition can be donated to training institutions, art programs, or community projects. These organizations can use the helmets for educational demonstrations, safety training exercises, or creative purposes, such as art installations. Contact local vocational schools, nonprofits, or art workshops to explore donation opportunities.

Repurposing:

A hard hat can find new life through creative repurposing. For instance, it can be converted into a garden planter, birdhouse, or even a decorative piece. Workplace or community events can encourage upcycling by hosting workshops or contests for repurposing old safety gear. Such initiatives not only reduce waste but also foster creativity and community engagement.

Hard hats are usually made of plastic and may have metal components, so they should not be thrown in the regular trash. If not recycled, hard hats are sent to landfills.

Always pay attention to the labels and manufacturer guidelines for the care, keeping, and disposal of your helmets and hard hats!

It is always a common question if any worker can use other workers safety helmet. It is suggested not to share safety helmet for maintaining proper hygiene. If your worker leaves and you are giving the helmet to another worker make sure you remove the sweatbands and harnesses, clean the shell properly with warm water and dry with a soft cloth and install new sweatbands and harnesses. This way it will ensure hygiene and longevity of the hard hat.

The price range for safety helmet can vary a lot. In USA the price starts from 10 USD (Click here to buy).

However, if you buy in bulk quantity it will be cheaper. A link for low price hard hats can be found here. Here you will get 40 cheapest hard hats in amazon in only 7 USD.

Cheap hard hats are not always bad in quality. You just have to make sure it has the tag for standard testing like ANSI Z89.1 inside it.

In Bangladesh the safety helmet price can be found from 200 BDT and can range up to 1000 BDT. You can contact us for order minimum 100 Safety Helmets. SafeBiz will inspect the helmets before delivering you and make sure you get the right product for right kind of people, works and industry.